MOULD CUSTOMIZATION, COOPERATIVE DEVELOPMENT

More than 30 years of professional R&D and production experience to help you succeed.

COOPERATIVE DEVELOPMENT

R&D SUBSIDIES FOR CUSTOMER

- We promise that the quotation time will not exceed 24 hours.

- The mold of general products will be completed within 25 days.

- The production cycle will not exceed 20 days.

Collapsible content

Customization subsidy

- If the one-time order quantity is more than 3,000 pieces, the mold fee will be subsidized by 30%-50%;

- if the order quantity is more than 5,000 pieces, the mold fee will be subsidized by 50%-70%;

- if the order quantity is 100.

R&D mold fee

If the cumulative order quantity of new products reaches 50,000 pieces, we will refund the full mold fee (or can be used for subsequent orders).

Price guarantee rules

After the first order unit price of the new product is confirmed, we promise that the price will only drop and not increase within two years (the price increase of raw materials will not exceed 20%).

ONE-STOP CUSTOMIZED SERVICE PROCESS

Tailor-made, fast proofing.

-

Customers provide samples/drawings.

-

The Engineering Department evaluates and issues a quotation.

-

The manufacturer and the customer reach an agreement on the price, and the mold is opened and the sample is produced after the mold fee is paid.

-

Customer confirms the sample and places an order after approving it.

-

The manufacturer signs a contract with the customer and pays a deposit to determine the delivery time.

-

The bulk of the goods is completed, the balance is paid, and logistics and distribution are carried out.

-

Customers receive bulk goods for inspection.

-

Satisfied with the completion, dissatisfied with the after-sales service.

We have a professional team

Provide one-stop solution services from R&D, design, sample preparation to production and testing, providing customers with the greatest convenience and the most timely delivery time

Professional and complete production workshops and equipment

Scientific process management, strict management of every link. Complete production equipment configuration; professional technicians are also equipped to operate, ensure production capacity and deliver on time.

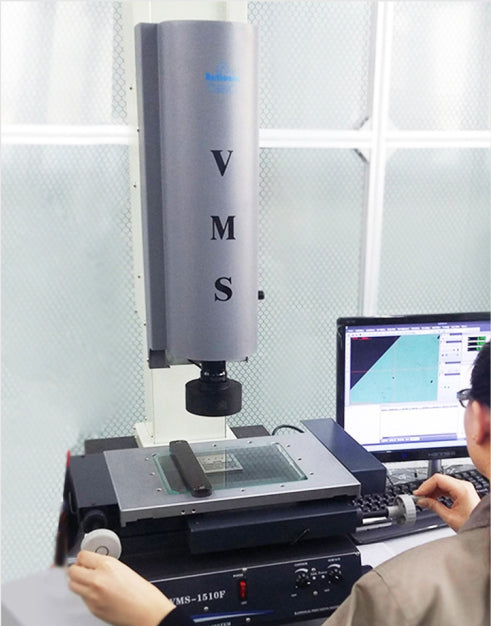

Provide comprehensive product testing

The quality inspection center is equipped with salt spray testers, aurora marking machine torque testers, high temperature aging machines, gas spring testers, film thickness testers, three-coordinate measuring machines, and imagers. It strictly implements overall quality control of raw material incoming, process, shipment and other links in accordance with the quality system and customer requirements.